Heat generation devices, known as tubular heating elements, are defined by their tubular shape. The majority of variations are intended for use in touch-surface heating or radiant heating. Read More…

Hotwatt manufactures a complete line of heating elements for a wide range of uses. We offer a broad product line from electric to cartridge and countless other systems as well. For those difficult applications, custom products are also available.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

Small-diameter, screened electrical resistance wires describe our heating elements. Braze them onto another metal piece; they'll fit a tight-bending radius, and the generation of heat at their placement reduces power consumption and loss. Call us or check our website for more information.

More Tubular Heating Element Manufacturers

What are Tubular Heating Elements?

Tubular heating elements are versatile, highly efficient electric heating devices used in a wide variety of industrial, commercial, and residential applications. Known for their reliability and durability, tubular heaters can be custom-bent into standard or unique shapes to match a specific heating requirement. These heating elements are essential components in thermal systems due to their adaptability and broad range of applications, offering precise, controllable heat transfer through conduction, convection, or radiation.

The enduring popularity of tubular heaters is largely attributed to their adaptability and robust construction. They are engineered to heat liquids, gases, air, and solid surfaces, and are commonly found in numerous heating assemblies. Tubular heating elements are manufactured in a variety of shapes and cross-sectional forms, including round, triangular, flat press, and custom-shaped profiles. This flexibility allows design engineers to select the optimal element for any given application—whether it’s a simple immersion heater or a complex industrial process heater.

With their ability to deliver uniform and consistent heating, tubular heating elements have become the backbone of many heat generation systems. Their applications span from water heating and air heating to process heating, freeze protection, and even foodservice equipment such as ovens and fryers. As a result, tubular elements are often the first choice for OEMs, engineers, and facilities managers seeking dependable and energy-efficient heating solutions.

How Tubular Heating Elements Work

At the heart of every tubular heating element is the principle of electrical resistance heating. These devices convert electrical energy into heat by passing current through a resistive wire, typically made from nickel-chromium alloys (nichrome), which is encased within a sheathed metal tube. The electrical resistance of the wire causes it to heat up as current flows through it. This heat is then transferred to the sheath and subsequently to the medium being heated, whether it’s air, liquid, or a solid surface. The design ensures even heat distribution and safe operation.

The construction of a tubular heating element generally includes:

- Resistance wire (nichrome)—the core heating element that generates heat via electrical resistance.

- Insulation (magnesium oxide powder)—surrounds the resistance wire, providing electrical insulation and excellent thermal conductivity.

- Metal sheath—commonly made from stainless steel, copper, Incoloy, or other corrosion-resistant metals, offering protection against physical damage and chemical exposure.

- Terminals—allow for safe electrical connection.

As electricity passes through the resistance wire, it produces intense, controllable heat. The surrounding insulation ensures that the heat is efficiently conducted to the outer sheath while minimizing electrical leakage and improving safety. The sheath itself transfers the heat directly to the process medium, whether by immersion in liquids (such as water or oil), direct contact with solids, or by radiating into air and gases.

This simple yet effective design is fundamental to countless heating solutions. For example, immersion heaters rely on tubular elements to safely and efficiently heat water in tanks and boilers, while air duct heaters use them for precise temperature control in HVAC and process air systems. The versatility and reliability of the design have made tubular heaters the industry standard for electric heating.

Tubular Heating Element Design Considerations

Selecting the right tubular heating element for your application involves careful consideration of a variety of design factors. By optimizing these factors, engineers ensure maximum performance, safety, and longevity for the heating system. Here are several key points to evaluate during the specification and procurement process:

1. Sheath Material Selection

The choice of sheath material directly impacts the element’s durability, corrosion resistance, and suitability for different environments. Common sheath options include stainless steel (for general-purpose and corrosive environments), copper (for water heating), Incoloy (high-temperature and corrosive settings), and titanium (for highly aggressive media such as acids and brines). Choosing the correct sheath material ensures optimal thermal performance and extends the service life of the element.

2. Watt Density Requirements

Watt density—measured in watts per square inch of heated surface—determines the intensity of heat output. Applications requiring gentle heating (such as oil baths or temperature-sensitive fluids) benefit from lower watt densities, while high-intensity industrial processes may demand higher watt densities for rapid heating. Proper watt density selection prevents overheating, minimizes scaling or coking, and maximizes efficiency.

3. Custom Shapes and Mounting Styles

Tubular heating elements can be bent or formed into almost any configuration, including straight, U-shaped, hairpin, or custom geometries. This flexibility allows designers to create elements for immersion, flange-mount, screw-in, or clamp-on applications, as well as for radiant and duct heating. Sizing and mounting options should be chosen based on space constraints, required heat distribution, and installation preferences.

4. Safety and Controls

Advanced safety features—such as explosion-resistant designs, integrated overheat protection, independent timing controls, and built-in temperature sensors—are critical in applications where safety is paramount. For example, explosion-proof tubular heaters are used in hazardous locations to prevent ignition of flammable atmospheres. Other common controls include thermostats, thermal cutoffs, and ground fault protection, all of which help ensure safe and reliable operation.

5. Insulation Material

The insulation surrounding the resistance wire must offer both high dielectric strength and efficient thermal transfer. Magnesium oxide (MgO) is the industry standard due to its excellent thermal conductivity and electrical insulation properties. In some cases, additional external insulation—such as ceramic coatings, fluoropolymers, or polyimides—may be used to improve safety, energy efficiency, or chemical resistance.

6. Environmental and Application Considerations

The operating environment significantly influences element design. For example, heaters used in ovens may require ceramic insulation to prevent contact with leaking oils or grease, while those for chemical processing must resist aggressive media and high temperatures. Always evaluate the specific chemical, thermal, and mechanical stresses the element will encounter during operation.

Need help choosing the right tubular heating element?

Explore our guide: How do I select the best tubular heating element for my application?

Applications of Tubular Heaters

Tubular heating elements are renowned for their extraordinary versatility and are found in a broad spectrum of industries and product categories. Their ability to deliver efficient, customizable heat output makes them indispensable for the following applications:

- Radiant Heating: Tubular heaters equipped with reflectors are widely used for radiant heating tasks—focusing infrared heat energy onto specific areas. These systems are ideal for warming, drying, and curing processes in manufacturing, printing, and automotive industries. When used in vacuum environments, watt density should be reduced by 20% to 30% to account for radiation as the primary heat transfer mode. For vacuum feedthrough setups, tubular heaters with aluminum or Inconel sheaths are common for their durability and thermal performance.

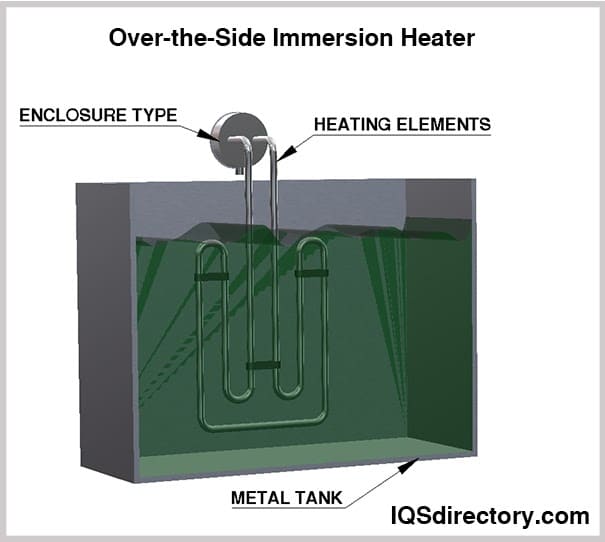

- Immersion Heating: Tubular heating elements are frequently used as immersion heaters in water tanks, boilers, chemical baths, and oil reservoirs. Their design allows for direct heat transfer to fluids, ensuring fast and uniform heating. Industries such as food processing, pharmaceuticals, and water treatment rely on immersion heaters for consistent temperature control and energy efficiency.

- Industrial and Commercial Equipment: Ovens, dryers, dishwashers, and a wide array of appliances utilize tubular heating coils for reliable, long-lasting temperature management. These elements are often encapsulated in ceramic insulation to enhance heat output and protect against contaminants. Materials such as nickel, steel, aluminum, copper, brass, and specialized alloys are chosen for their superior electrical and thermal conductivity, as well as resistance to corrosion and wear.

- Process Heating: Numerous industries—including plastics, packaging, food and beverage, and petrochemical—use tubular heaters for process heating, where precise temperature regulation is crucial for quality and productivity. Custom-formed elements can be integrated into complex assemblies for heat tracing, mold heating, and die heating.

- Space and Comfort Heating: Tubular elements power space heaters, baseboard units, and radiant panels for both commercial and residential environments. Their robust construction and controllable output make them ideal for safe, cost-effective comfort heating.

- Freeze Protection and Pipe Heating: Tubular heating cables and rods are installed along pipes, tanks, and vessels to prevent freezing, condensation, or viscosity changes in temperature-sensitive fluids. These solutions are vital in water treatment plants, oil refineries, and chemical processing facilities.

- Corrosive and High-Temperature Applications: In environments where aggressive chemicals or extreme temperatures are present, tubular heaters with specialized sheaths—such as stainless steel, Incoloy, or titanium—ensure reliable, long-term performance without degradation or failure.

- Custom Heating Solutions: Engineers frequently specify tubular elements for custom heating assemblies, including laboratory equipment, testing chambers, medical devices, and pilot plants, due to their nearly limitless formability and configurable wattage.

The broad adaptability of tubular heating elements means they are often found wherever precise, safe, and energy-efficient electric heating is required. This widespread utility drives ongoing innovation in heater design, materials, and control systems, ensuring that tubular heaters remain at the forefront of modern thermal technology.

Choosing the Proper Tubular Heating Element Supplier

Selecting a reliable tubular heating element manufacturer or distributor is crucial to achieving optimal performance and cost-effectiveness in your thermal application. When evaluating suppliers, consider the following factors to ensure you source the right product for your needs:

- Technical Expertise and Customization: Does the supplier offer engineering support, technical expertise, and the ability to design custom heating elements? Look for manufacturers with experience in your specific industry—whether you require high-temperature elements for industrial ovens, corrosion-resistant heaters for chemical processing, or sanitary designs for food and beverage applications.

- Quality Assurance and Certifications: Confirm that the supplier adheres to industry standards and certifications (such as ISO 9001, UL, CSA, or CE). High-quality manufacturing ensures safe, long-lasting elements and reduces the risk of equipment downtime.

- Material and Construction Options: Assess the range of available sheath materials, watt densities, shapes, and mounting styles. A reputable supplier should offer a comprehensive selection to match your precise requirements.

- Lead Times and Inventory: How quickly can the supplier deliver standard or custom tubular elements? Reliable suppliers maintain robust inventories and streamlined production processes to minimize lead times and support urgent projects.

- Support and After-Sales Service: Responsive customer service, technical support, and warranty coverage are important for troubleshooting, maintenance, and long-term satisfaction.

- Competitive Pricing and Value: While price is a factor, prioritize suppliers who offer value-added services, engineering support, and proven reliability over the lowest-cost option.

To ensure you have the most productive outcome when purchasing tubular heating elements from a tubular heating element supplier, it is important to compare several companies using our directory of tubular heating element suppliers. Each tubular heating element supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each tubular heating element business website using our proprietary website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple tubular heating element companies with the same form.

Frequently Asked Questions About Tubular Heating Elements

What industries use tubular heating elements?

Tubular heating elements are critical components in industries such as food and beverage processing, pharmaceuticals, petrochemicals, plastics, automotive manufacturing, HVAC, water and wastewater treatment, laboratory equipment, and commercial appliances. Their adaptability and robust design make them suitable for both light-duty and heavy-duty applications.

What are the main benefits of using tubular heating elements?

- Versatility: Can be custom-formed for nearly any heating task.

- Energy Efficiency: Direct conversion of electrical energy to heat reduces waste and operational costs.

- Durability: Rugged construction and corrosion-resistant materials ensure long service life.

- Precision: Consistent, controllable heat output supports process accuracy.

- Safety: Built-in protections and insulation materials minimize risks of fire, shock, or overheating.

How do I determine the right wattage and configuration for my application?

Sizing a tubular heating element involves calculating the required heat load, assessing the thermal properties of the medium, and selecting appropriate watt density, voltage, and mounting style. Consult with a knowledgeable supplier or use our tubular heating element selection guide for detailed assistance.

What maintenance is required for tubular heating elements?

Regular inspections for signs of wear, corrosion, or scaling, as well as functional checks of electrical connections and safety controls, are recommended. For immersion heaters, periodic cleaning may be necessary to remove mineral buildup and maintain efficiency. Always follow the manufacturer’s maintenance guidelines.

Ready to Source Tubular Heating Elements?

Compare top-rated tubular heating element manufacturers and suppliers using our comprehensive directory. Request quotes, review specifications, and connect with industry experts to find the ideal solution for your heating requirements. Get started now or explore our additional resources for in-depth technical guidance and buying tips.

Related Resources and Further Reading

- What are immersion heater elements and how are they used?

- Ceramic vs. tubular heating elements: Which is best for your application?

Get Expert Assistance

Still have questions about tubular heating elements or need help with product selection? Contact our technical team for personalized recommendations, or use our RFQ form to request pricing and lead time information from multiple qualified suppliers.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services