The term “heating elements” refers to any and all heat generation equipment in electric heaters. Found in equipment of all shapes and sizes and with a variety of configurations and materials, heating elements all have the same goal: to convert electrical energy into heat energy up to 1300°F, and then distribute said heat energy through or to solids, liquids or gases (including air) via convection, conduction or radiation. Read More…

Hotwatt manufactures a complete line of heating elements for a wide range of uses. We offer a broad product line from electric to cartridge and countless other systems as well. For those difficult applications, custom products are also available.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

Small-diameter, screened electrical resistance wires describe our heating elements. Braze them onto another metal piece; they'll fit a tight-bending radius, and the generation of heat at their placement reduces power consumption and loss. Call us or check our website for more information.

More Heating Elements Manufacturers

Applications

Heating elements are indispensable components in both consumer appliances and industrial equipment, where precise, efficient, and reliable heat generation is essential for a wide range of operations. In the residential sector, heating elements are foundational to the operation of electric heaters, hair dryers, ovens, toasters, coffee makers, and water heaters. For example, electric stoves and ovens use heating elements to maintain accurate cooking temperatures, while toasters and clothes dryers depend on these components for efficient, even heating. Immersion heaters are commonly found in home water heaters and electric kettles, ensuring rapid hot water delivery and consistent thermal performance.

In industrial and commercial environments, heating elements are critical for manufacturing processes and specialized applications. Diffusion pumps utilize heating elements to vaporize substances and create high-vacuum conditions, essential for processes such as semiconductor fabrication and scientific research. Kilns and furnaces depend on robust heating elements to reach the extreme temperatures necessary for ceramics, metal forging, and glass production. Liquid immersion heaters are used extensively in chemical processing, food and beverage manufacturing, pharmaceutical production, and water treatment facilities, where direct and controlled heating of fluids is required. These immersion heaters, often made from corrosion-resistant materials such as stainless steel, provide rapid and uniform heat transfer for optimal process efficiency.

Additional applications include plastic extrusion, where band heaters and coil heaters maintain the required temperature for plasticization; packaging equipment, which uses cartridge heaters for sealing and forming materials; and HVAC systems, where duct heaters and tubular elements ensure climate control in commercial and industrial buildings. In the automotive industry, heating elements are used in defrost systems, battery warmers, and seat heaters, improving safety and comfort for end-users.

Heating elements also play a vital role in laboratory and research settings, providing precise thermal control for incubators, autoclaves, and analytical instruments. Additionally, they are used for freeze protection in piping systems, frost prevention in refrigeration equipment, and in de-icing applications for aircraft and wind turbines. Their versatility, reliability, and energy efficiency make them the cornerstone of temperature regulation in countless critical systems.

Key Benefits of Heating Elements:

- Consistent and uniform heat delivery for process reliability

- Precise temperature control for enhanced product quality

- Energy efficiency to minimize operational costs

- Flexible configurations for custom applications

- Long service life and minimal maintenance requirements

- Compatibility with advanced automation and smart controls

Questions to Consider:

- What type of heating element is best for your specific application?

- How do you determine the appropriate wattage and material for your heating needs?

- Are you seeking energy-efficient or rapid-heating solutions for your equipment?

- Do you need corrosion-resistant elements for harsh environments?

The History of Heating Elements

The evolution of heating element technology spans more than a century, shaping the course of modern industry and domestic life. The origins can be traced back to 1879, when Thomas Edison introduced his incandescent light bulb, using a carbon filament that produced both light and heat. This innovation laid the groundwork for future developments in electric heating.

During the late 19th century, physicists Julius Robert Mayer and James Prescott Joule pioneered the first law of thermodynamics, which clarified the principles of heat generation and energy conversion. Their work inspired inventors such as Benjamin Waddy Maughan, who created the first gas water heater in 1868, and Edwin Ruud, who patented the first electric water heater in 1889—ushering in a new era of safe, efficient home heating solutions.

The discovery of silicon carbide by Edward G. Acheson in 1891 further advanced the field, providing a durable, high-temperature material that remains in use today for industrial heating and semiconductor manufacturing. In 1905, Albert Marsh’s invention of nichrome wire (an alloy of nickel and chromium) revolutionized the industry by enabling heating elements to reach significantly higher temperatures. Nichrome quickly became the standard for electric toasters and a variety of other household and commercial devices.

The widespread adoption of heating elements accelerated after World War II, as economic prosperity and technological advancements brought electrical appliances into mainstream households. Bar heaters, electric radiators, and oil-filled radiators became widely available, with innovations such as portable radiant bar heaters offering convenient and immediate warmth. However, evolving safety standards and consumer awareness led to more robust protective features and the development of safer, more efficient heater designs.

By the 1960s and 1970s, energy efficiency became a priority. Storage heaters emerged in the UK, leveraging electric heating elements to store heat in thermal bricks, which could then be released during peak demand periods. The oil crisis of the 1970s further spurred the adoption of electric heating solutions, and the 1990s saw the introduction of advanced ceramic-based elements, screen-printed metal-ceramic tracks, and modern electric radiators offering faster, more precise heating control.

The digital revolution of the 21st century has redefined heating element technology. Today’s modern smart heating systems feature programmable thermostats, Wi-Fi connectivity, touchscreens, and advanced sensors for real-time monitoring and optimization. Manufacturers now prioritize sustainability and energy conservation, reducing reliance on fossil fuels and integrating renewable energy sources where possible.

Are you looking to upgrade to a modern, energy-efficient heating system? Explore the latest smart heating technology and discover how advanced heating elements can lower your energy costs while maximizing comfort and safety.

Characteristics

Heating elements operate based on Joule heating (also known as resistive or ohmic heating). When electrical current passes through a material with electrical resistance, the energy is converted into heat. The effectiveness of a heating element depends on its material properties, geometry, and the applied electrical load.

Key characteristics of heating elements include:

- Resistivity: The electrical resistance per unit length and cross-sectional area, measured in ohms per meter, which determines how much energy is converted to heat.

- Wattage (kW load): The power rating indicates the maximum electrical load the element can handle safely and efficiently.

- Thermal Conductivity: The material’s ability to transfer heat to the surrounding environment or medium.

- Temperature Coefficient: Describes how the resistance of the element changes with temperature, impacting self-regulation and stability.

- Durability and Corrosion Resistance: Essential for longevity, especially in harsh or wet environments.

- Size and Form Factor: Customizable shapes and configurations to fit specific applications, from compact cartridge heaters to large tubular elements.

Selecting the right heating element involves balancing these characteristics against application requirements, including temperature range, environmental conditions, and regulatory standards.

Heating Element Types

There is a diverse array of heating element types to address the unique needs of industries and applications. Below is an in-depth overview of key types, their features, and typical use cases.

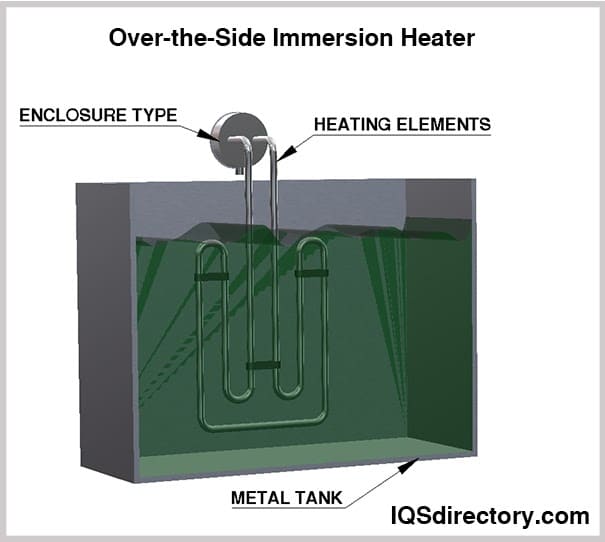

Immersion Heating Element

Immersion heating elements are engineered to be submerged directly into liquids or gases, providing fast, energy-efficient, and uniform heating. Commonly used in water heaters, boilers, chemical process tanks, and oil heaters, these elements are constructed from corrosion-resistant materials such as stainless steel, titanium, or Incoloy. They feature protective sheaths to prevent chemical attack and ensure long operational life. Immersion heaters are ideal for applications requiring direct contact heating and rapid temperature ramp-up.

Quartz Heating Element

Quartz heating elements utilize a quartz tube housing a resistive wire or filament. When energized, they emit infrared radiation for fast, targeted heating. Quartz elements are preferred for paint curing, powder coating, thermoforming plastics, and zone-controlled industrial heating. Their ability to deliver instant heat makes them suitable for applications in the electronics, automotive, and printing industries.

Flexible Heating Element

Flexible heating elements are designed for adaptability, capable of conforming to curved, uneven, or irregular surfaces. Constructed from materials like silicone rubber or polyimide film, these elements deliver even, controlled heat to sensitive equipment, medical devices, aerospace components, and electronics. Their low profile and customizable shapes make them ideal for applications where space is limited or where traditional rigid heaters cannot be used.

Infrared Heating Element

Infrared heating elements generate heat by emitting electromagnetic waves in the infrared spectrum. They are highly efficient for large-scale heating, such as industrial ovens, pressure vessels, water treatment plants, and boilers. Infrared heaters also excel in drying processes, cure systems, and dehumidification, thanks to their ability to deliver directional, rapid, and energy-saving heat.

Wire Heating Element

Wire coil heating elements are among the most widely used designs for both industrial and commercial heating. Typically made from nichrome, Kanthal, or cupronickel, these coils or ribbons serve as resistors to deliver reliable, consistent heat. Applications range from surface treatment heaters and kilns to drying ovens and massagers. Engineers can customize coil geometry to achieve precise heating profiles and uniform distribution.

Ceramic Heating Element

Ceramic heating elements are used for convection heating where uniform and stable temperatures are required. Found in space heaters, furnaces, and semiconductor processing, ceramic elements offer high durability and excellent electrical insulation. Types include molybdenum disilicide (MoSi₂) for high-temperature applications and PTC (Positive Temperature Coefficient) ceramics for self-regulating heaters.

Molybdenum Disilicide Element

Molybdenum disilicide is a hybrid material with a high melting point (3690ºF) and superb oxidation resistance, making it suitable for glass production, steel manufacturing, and high-temperature furnaces.

PTC

PTC ceramics are widely used in automotive defrost heaters, space heaters, and professional hair dryers. They provide safe, self-limiting temperature control, reducing overheating risks and improving energy efficiency.

Electric Heating Element

Electric heating elements are at the core of most industrial electric heaters, delivering reliable, high-performance heating for process equipment, packaging lines, food processing, and plastics manufacturing.

Cartridge Heater

Cartridge heaters are compact, high-watt density elements designed for insertion into drilled holes, offering precise and localized heating for metal molds, plastic forming dies, packaging machinery, and food service equipment.

Metal-based Heating Elements

Metal-based heating elements are constructed from conductive metals such as nichrome, Kanthal, and cupronickel. They are used extensively in household appliances (e.g., irons, toasters, ovens) and industrial machinery. Key subtypes include:

Nichrome Heating Element

Nichrome’s high resistance and durability make it the preferred choice for electric heaters, toasters, and hair dryers. The typical composition is 80% nickel and 20% chromium.

Resistance Wire Heating Element

Resistance wire elements—straight or coiled—are designed for flexibility and ease of integration into various products. They are commonly found in appliances and industrial heating systems where custom shapes and wattages are required.

Coil Heater

Coil, band, and strip heaters are used in extrusion channels and hoppers to keep materials molten and process-ready throughout the manufacturing cycle.

Composite Heating Elements

Composite heating elements combine ceramics and metals for improved performance, efficiency, and longevity. Variants include tubular elements, removable ceramic core elements, and carbon fiber composite elements.

Tubular Heating Element

Tubular heating elements are versatile, robust, and highly customizable. They are widely used in ovens, dishwashers, HVAC duct heaters, and refrigeration equipment.

Radioactive Heating Element

- Radioactive or heat lamp elements emit infrared radiation for food warming, space heating, and industrial drying.

- Gold-coated lamps filter visible light and maximize infrared output for targeted heating applications.

- Ruby-coated lamps offer a budget-friendly alternative with higher visible glare.

- Uncoated clear lamps are used in high-intensity industrial heat processing.

Removable Ceramic Core Element

These elements provide easy replacement and maintenance, making them ideal for pressurized fluid heating in industrial processing.

Carbon Fiber Composite Element

Carbon fiber heating elements are corrosion-resistant, lightweight, and capable of withstanding extreme temperatures. They are used in aircraft de-icing, consumer heaters, and high-performance industrial systems.

Need help choosing the right heating element for your application? Contact our experts or browse our comprehensive manufacturer listings for tailored solutions.

Accessories

A variety of heating element accessories are available to enhance performance, improve safety, and extend the lifespan of your heating systems. Selecting the right accessories is crucial for optimizing your installation and ensuring compliance with safety regulations.

Key Accessories and Their Functions:

- Wire and element holders: Secure heating elements in place, preventing movement and maintaining optimal positioning for uniform heat distribution.

- Thermal switches: Monitor temperature and automatically disconnect power if preset limits are exceeded, preventing overheating and fire hazards.

- Pliers: Facilitate the installation and maintenance of heating elements, especially when bending or shaping is required.

- Braided wire: Improves flexibility and durability of electrical connections, minimizing the risk of fatigue and breakage caused by vibration or movement.

- Silicone O-rings: Create watertight seals for immersion heaters and other liquid-contact applications.

- Bolts and fasteners: Ensure stable mounting and prevent loosening during operation.

- Adaptors and extension cords: Provide compatibility with various power supplies and extend reach in challenging installations.

- Power cords: Deliver safe, reliable electrical connections from the element to the power source.

- Electrical boxes: Enclose and protect wiring and connections, enhancing safety and compliance.

Where to Buy Heating Element Accessories:

- Direct from heating element manufacturers or authorized distributors

- Online retailers specializing in industrial or household heating equipment

- Local hardware and electrical supply stores

- Consult with industry experts for recommendations on compatible accessories for your heating system

How to Select the Right Accessories:

- Assess your specific application and environmental conditions

- Consider factors like safety, durability, and compatibility

- Refer to manufacturer guidelines for recommended accessories

- Consult with professionals for custom or complex installations

Proper Care for Heating Elements

Proper care and maintenance extend the service life and ensure the safe operation of heating elements. Key considerations include correct pairing with equipment specifications, regular inspection for wear or damage, and prompt replacement of failing components.

Maintenance Best Practices:

- Ensure voltage and wattage ratings match application requirements

- Periodically inspect for signs of discoloration, deformation, or burn marks

- Test electrical resistance using the formula: R = (V x V) ÷ P (where R = resistance, V = voltage, P = power)

- Use a multimeter to verify resistance values

- Replace elements that show significant deviation or deterioration

- Follow safety protocols: disconnect power, drain systems (for water heaters), and consult professionals as needed

If your device is losing heating efficiency, it’s often more cost-effective to replace the element—unless, in the case of small appliances, replacement of the entire unit is warranted. Manufacturers typically offer replacement elements and guidance for installation or can provide professional service.

Step-by-Step: How to Test and Replace a Heating Element

- Visually inspect the coil for damage or discoloration.

- Calculate the expected resistance value using the appropriate formula.

- With the device unplugged, use a multimeter to measure the element’s resistance.

- Compare measured values to calculations to assess element health.

- Replace the element if values differ significantly or if physical damage is present.

Note: For water heaters or immersion devices, always drain the tank and ensure complete power isolation before servicing.

Standards

Heating elements must comply with strict industry standards and safety regulations to ensure dependable performance and minimize risks. In the United States, organizations such as UL (Underwriters Laboratories), ANSI (American National Standards Institute), and the NFPA (National Fire Protection Association) set forth guidelines for design, manufacturing, and installation.

The National Electrical Code (NFPA 70) is a key reference for electrical installations, including wiring, overcurrent protection, and grounding of heating elements in residential, commercial, and industrial settings. Adhering to these standards ensures:

- Safe operation and reduced risk of fire or electrical shock

- Compliance with legal and insurance requirements

- Reliable, long-lasting performance

- Compatibility with other certified components

Using non-compliant or substandard heating elements can void warranties, increase liability, and result in fines, equipment failure, or hazardous incidents. Conversely, certified elements offer peace of mind, lower maintenance costs, and improved operational efficiency.

Are you seeking certified heating elements for your next project? Make sure to verify product certifications and consult with reputable manufacturers to ensure compliance with all applicable standards.

How to Find the Right Manufacturer

Choosing the right heating element manufacturer is critical for achieving optimal results, whether you need standard replacement parts or custom-engineered solutions. Our comprehensive directory of heating element manufacturers provides detailed profiles, showcasing each company’s expertise, capabilities, and certifications. By leveraging our intuitive website previewer, you can quickly assess supplier strengths and product offerings.

Use our streamlined RFQ (Request for Quote) form to reach out to multiple manufacturers simultaneously, saving time and effort during your procurement process. Each listing includes direct contact forms for personalized inquiries and support.

Questions to Consider When Evaluating Heating Element Manufacturers:

- What industries and applications do they specialize in?

- Do they offer custom design and engineering support?

- Are their products certified to meet relevant industry standards?

- What are their lead times, pricing, and after-sales services?

- Can they provide references or case studies for similar projects?

By conducting thorough research and comparing multiple suppliers, you can identify the best partner for your heating element needs—whether for OEM manufacturing, process upgrades, or new equipment installations.

Ready to source heating elements for your next project? Visit our Electric Heaters website for additional resources, product guides, and direct access to leading manufacturers.

What are the main applications of heating elements in residential and industrial settings?

What are the key factors to consider when selecting a heating element?

What types of heating elements are available, and what are their common uses?

What are the main benefits of using heating elements?

How can you properly care for and maintain heating elements?

What safety standards and regulations apply to heating elements?

Which accessories are recommended for heating element installations?

How should you choose a heating element manufacturer?

What are the main applications of heating elements?

Heating elements are widely used in residential appliances such as electric heaters, ovens, toasters, coffee makers, and water heaters. In industrial and commercial settings, they are critical for kilns, furnaces, chemical processing, food and beverage production, pharmaceutical manufacturing, HVAC systems, and laboratory equipment. They are also used in automotive defrost systems, de-icing for wind turbines and aircraft, freeze protection, and scientific research instruments.

What types of heating elements are available?

There are many heating element types, including immersion heaters, quartz elements, flexible silicone and polyimide heaters, infrared heaters, wire coil elements, ceramic heaters (such as PTC and molybdenum disilicide), cartridge heaters, metal-based elements (nichrome, Kanthal, cupronickel), tubular elements, carbon fiber composite elements, and removable ceramic core elements. Each type is designed for specific applications and performance requirements.

What are the key characteristics to consider when selecting a heating element?

Key characteristics include resistivity, wattage (power rating), thermal conductivity, temperature coefficient, durability, corrosion resistance, and size or form factor. The right heating element is selected by balancing these characteristics against application requirements such as temperature range, environmental exposure, and compliance with safety or regulatory standards.

How can I properly care for and maintain heating elements?

Ensure voltage and wattage match your application, regularly inspect for discoloration or deformities, test resistance using a multimeter, and promptly replace failing components. Always disconnect power and follow recommended safety protocols during maintenance. For immersion or water heaters, drain the system before servicing, and consult professionals as needed to ensure proper care.

What standards and certifications should heating elements comply with?

Heating elements should comply with standards set by organizations such as UL (Underwriters Laboratories), ANSI (American National Standards Institute), and the NFPA (National Fire Protection Association), particularly the National Electrical Code (NFPA 70). Certified products ensure safety, legal compliance, and compatibility with other certified components.

What accessories are available for heating element installations?

Heating element accessories include wire and element holders, thermal switches, pliers, braided wire, silicone O-rings, bolts and fasteners, adaptors and extension cords, power cords, and electrical boxes. These accessories help improve safety, facilitate installation, extend lifespan, and ensure optimal performance of your heating systems.

How do I choose the right heating element manufacturer?

Select manufacturers based on their experience with your specific industry and applications, the availability of custom design or engineering support, product certifications, pricing, lead times, and after-sales service. Research multiple suppliers, compare offerings, and request references or case studies to ensure they meet your technical and regulatory requirements.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services