Offering fast and efficient heating, immersion heating elements are cost-effective heating solutions. A few of the materials that are often heated by immersion heating elements include mild acids, oils, water, air, salts, plating baths, and a variety of chemical solutions. Read More…

Hotwatt manufactures a complete line of heating elements for a wide range of uses. We offer a broad product line from electric to cartridge and countless other systems as well. For those difficult applications, custom products are also available.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

Small-diameter, screened electrical resistance wires describe our heating elements. Braze them onto another metal piece; they'll fit a tight-bending radius, and the generation of heat at their placement reduces power consumption and loss. Call us or check our website for more information.

More Immersion Heater Element Manufacturers

Since immersion heating elements are used to heat many corrosive substances, they are often covered with a protective outer sheath. A wide range of sheath materials used includes titanium, stainless steel, Incoloy, copper, brass and cast iron. However, different sheath materials work best for different substances. For example, stainless steel is best for mild acids, while Incoloy is best for high-temperature air and gasses as well as alkaline solutions.

Common industries that utilize immersion heater elements include automotive, manufacturing, wastewater, commercial, electronics, and aerospace for applications such as heat transfer systems, storage tanks, oil and water heaters, railroad tank cars, process systems, and boilers.

A typical construction of an immersion heater includes a tubular heating element and an electrical terminal that remains outside of the substance.

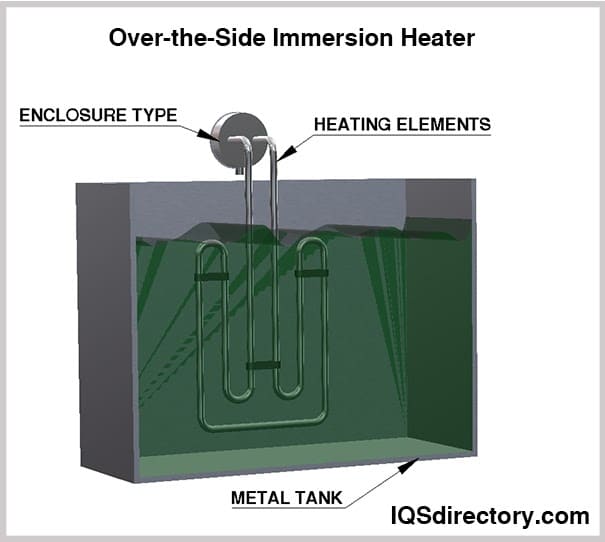

Generally, immersion heating elements come in three main style types: over-the-side, flanged (through-the-side), and threaded (screw-plug).

The over-the-side style of immersion heating elements is designed for containers in which through-the-side immersion heating elements cannot be easily installed. Thus, the immersion heater is installed through the top of the container, allowing the heating element to lie along the side or at the bottom of the container.

Flanged immersion heaters are a through-the-side style. They are usually round or square-shaped and are welded or brazed onto pipe flanges. They are then bolted to a matching flange that has been welded to a container wall. This style of immersion heater is the most common method used for heating liquids.

Threaded, or screw-plug, immersion heaters are very similar in style to flanged immersion heaters. Instead of a flange, the hairpin bent tubular heating element is welded to a plug that is screwed into the container through a threaded hole in the container wall. Screw plug immersion heaters work best in process water heating and freeze protection applications.

Additional Reading...

How to Replace Heating Elements in Water Heaters

In winters, nothing is more relaxing than having a hot water shower. Well, that is a necessity, or maybe a luxury, for households. Water is also used in numerous industrial applications for successful completion of production. Both homes and businesses use different types of electric heaters to fulfill their need for heaters.

Almost all water heaters have heating elements, an important part of the system, that is responsible for warming up or boiling the water. If your appliance is not heating up, then there could be a problem in the heating element. No matter how old your heater is, if its heating element is in fine and working condition, it will perform just like a newly unpacked appliance.

If your water heater’s performance has downgraded recently, you can carry out a little assessment and replace the element on your own.

The Elements

Modern electric water heaters have two elements, while ones of an earlier generation have just a single unit. To check whether your appliance is new or old, you can look at the top and bottom of your heater for elements. If it has just one element, then your appliance belongs to the earlier technology and if it has two elements, one at the top and other on the bottom, then yours is a new machine.

Another easy method to ascertain this is to find the website of your water heater manufacturer and find the model number and its release date.

Once you have located the element, you can use a multimeter or voltmeter to check the response of the part. If the resistance in the element is very high, then it probably is a bad element, which needs to be replaced.

You should buy new and branded heating elements only, if you are going to replace the damaged ones by yourself. Using a third party or compatible element will lead to complete impairment of your appliance. You can order original parts from your nearby brand store or a renowned supplier of your heater brand.

Wattage and Voltage

Every electric appliance comes with its wattage and voltage consumption information. Wattage means, how much electricity it will consume and voltage means, which amperage it will need to work smoothly. If the machine does not get the required supply of voltage, then it will be at the risk of collapsing. Generally, home-based water heaters are a 4500 watt appliance that need 240 volts to run smoothly. If low voltage is supplied, the machine will have to work harder, which will lead to overuse and ultimately damage.

To make the best use of your water heater and to prevent the heating element from collapsing, you need to have an adequate voltage control system installed at your place.

If you are going to buy heating element for replacement, then you should know which type of element your machine will support. Usually, there are three types of heating elements, flange, raised flange, and screw type. Additionally, there are also low and high-density heating elements available. If at any stage, you feel any confusion while changing the element, it is advisable to call in an expert service to do this job.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services