Traditional heating solutions have been a mainstay in our homes and industries for many years. These solutions, often made from stiff materials like nickel and chromium, have been crucial in everyday appliances and industrial equipment. Read More…

Hotwatt manufactures a complete line of heating elements for a wide range of uses. We offer a broad product line from electric to cartridge and countless other systems as well. For those difficult applications, custom products are also available.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

Small-diameter, screened electrical resistance wires describe our heating elements. Braze them onto another metal piece; they'll fit a tight-bending radius, and the generation of heat at their placement reduces power consumption and loss. Call us or check our website for more information.

More Flexible Heating Element Manufacturers

However, they had their drawbacks - they couldn't bend to fit into different shapes and sometimes didn't heat things very evenly.

This is where flexible heating elements come into play, marking a significant innovation in the world of heating technology. Unlike the old, rigid types, these new elements are designed to be flexible. They can twist and bend to fit into various spaces, making them super versatile and opening up new possibilities for their use.

The Evolution of Heating Elements

Heating elements have seen quite a transformation. Initially, these elements were basic and suitable for straightforward tasks in simple machines and household items. Their design was focused more on function than flexibility.

But as technology progressed, so did heating elements. When compared to traditional materials used in heating elements, like nichrome (a nickel-chromium alloy), graphene offers several advantages:

Energy Efficiency: Due to its high electrical and thermal conductivity, graphene can heat up quickly and distribute heat more evenly. This efficiency can lead to lower energy consumption, as less heat is wasted and the desired temperature is reached faster.

Durability in Flexion: Traditional materials like nichrome can become brittle and break if bent, but graphene can withstand significant bending and twisting without damage. This makes graphene-based heaters more durable in applications where flexibility is key.

Heat Distribution: Traditional heating elements can suffer from uneven heat distribution, leading to hotspots. Graphene's superior thermal conductivity allows for more uniform heat distribution, enhancing both safety and performance.

Size and Integration: The thinness of graphene enables it to be used in applications where traditional materials are too bulky. This allows for sleeker product designs and opens up new possibilities in product development.

These new materials allow heating elements to be both flexible and effective at heating. This shift was significant – it meant heating elements could now be integrated into a wider range of products, from intricate medical devices to sleek consumer electronics.

Current State of Flexible Heating Elements

Today, flexible heating elements are at the forefront of heating technology. Their applications span across various sectors. In homes, they're found in advanced appliances and even in wearable technology that keeps us warm. In the automotive world, these elements are making vehicles more comfortable, with applications like heated seats and window defoggers.

In the medical field, flexible heating elements have improved patient care. They're used in devices that monitor health and provide therapeutic heat, enhancing both comfort and treatment.

The appeal of these elements lies in their ability to adapt to different shapes and needs, making them highly versatile and efficient. They're a prime example of how innovation in design can lead to more effective and user-friendly technology.

Advancements in Materials and Manufacturing

In the world of flexible heating elements, there's been some exciting progress in the materials used to make them. Scientists and engineers are now using graphene, which is a super-thin and strong material, and advanced polymers, which are a type of plastic that can conduct electricity. These materials are game-changers because they're not only flexible but also really good at conducting heat, which makes the heaters more efficient.

On top of that, the way these heaters are made is also improving. Manufacturing processes have changed to allow for the production of flexible heaters that are not only more efficient in their heating capabilities, but also more durable and less expensive to produce. This means that these heaters can be used in more products and by more people, making them a serious contender in the heating industry.

Emerging Trends and Future Applications

Looking ahead, there are some cool things on the horizon for flexible heating elements. One of the biggest trends is integrating them with the Internet of Things (IoT). This means that these heaters can be connected to the internet and controlled remotely, making them part of smart home systems or industrial applications.

Imagine being able to control the temperature of your heated jacket or car seat with just a tap on your smartphone. Better yet, imagine it automated to start 10 minutes before you leave for work!

As for the future, the possibilities are almost endless. We could see these flexible heaters being used in space exploration, helping to keep equipment and astronauts warm in the extreme cold of space. They could also play a big role in flexible electronics, like roll-up tablets and wearable tech, providing heat where it's needed in these cutting-edge devices.

Challenges and Research Focus

Of course, with any new technology, there are challenges to overcome. For flexible heating elements, some of the big challenges include making sure they're durable enough to last a long time. To help achieve this, the devices must be efficient in their energy use.

Researchers are busy finding solutions. They're experimenting with new materials and designs to make these heaters even better. They're also working on ways to produce them more efficiently and at a lower cost, so they can be used in even more products and applications.

This research and focus on improvement are what's driving the field forward, pushing the boundaries of what's possible with flexible heating elements and heating technology as a whole.

Environmental Impact of Flexible Heating Elements

The environmental impact of flexible heating elements is a key focus, especially in today’s eco-conscious world. These elements stand out for their energy efficiency, since they use less power compared to traditional heating methods. This efficiency comes from their ability to provide direct heat transfer, reducing the amount of wasted energy in the system.

Furthermore, the sustainability of these elements is also noteworthy. Many are made with environmentally friendly materials and are designed to have a longer lifespan, which means less waste. By reducing energy consumption and waste, flexible heating elements can also play a role in lowering our carbon footprint and helping to meet green energy goals.

Industry Insights on Flexible Heating Elements

Industry experts are quite optimistic about the future of flexible heating elements. They see these advancements not just as a trend but as a long-term shift in the heating solutions industry. Experts predict that the use of flexible elements will continue to grow, especially as they become more efficient and versatile.

These experts also foresee a future where flexible heating elements are integrated into even more aspects of daily life – from smart homes to advanced transportation systems. They believe that the potential for these elements to be combined with renewable energy sources could open up new, more sustainable ways to heat our spaces and devices.

Conclusion

The impact of flexible heating elements on the heating solutions industry is nothing short of transformative. They are not just improving existing products; they are enabling the creation of new ones. Their flexibility, efficiency, and adaptability represent a significant leap forward in heating technology.

Looking to the future, it’s exciting to think about how these elements will continue to evolve and integrate into our lives. The possibilities for innovation and improvement in heating technology seem almost limitless.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

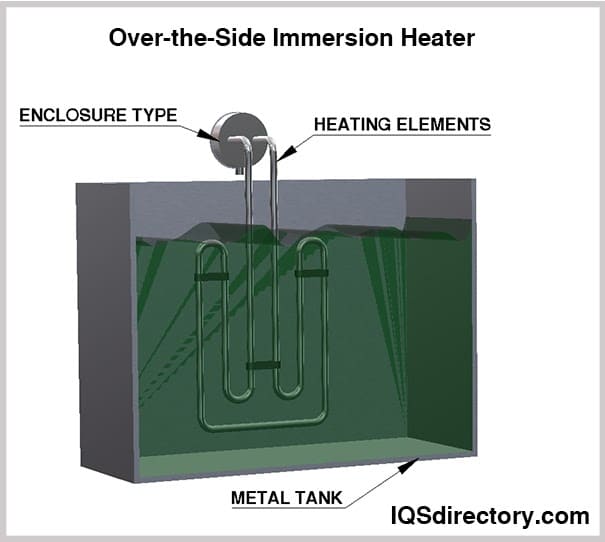

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services