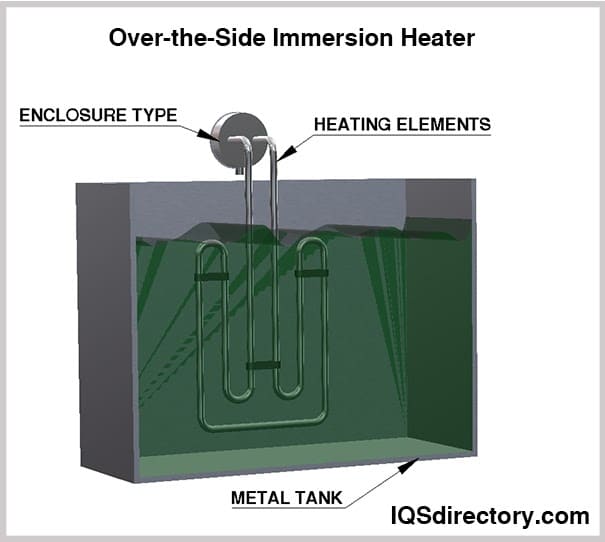

Different heating element configurations are appropriate for different applications. An immersion heating element, for example, is used only in contexts in which the heating element will be immersed in the materials that it is used to heat. This would make an immersion heating element inappropriate for use in a dryer. Read More…

Hotwatt manufactures a complete line of heating elements for a wide range of uses. We offer a broad product line from electric to cartridge and countless other systems as well. For those difficult applications, custom products are also available.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

Small-diameter, screened electrical resistance wires describe our heating elements. Braze them onto another metal piece; they'll fit a tight-bending radius, and the generation of heat at their placement reduces power consumption and loss. Call us or check our website for more information.

More Dryer Heating Element Manufacturers

Likewise, consumer clothes dryers do not require the same kind of heat generation tools as do industrial dryers; most consumer clothes dryers involve the controlled burning of natural gas for heat generation. Commercial dryers come in all shapes and sizes and are used for many purposes. They are used in health care facilities for instrument sanitation, in laboratories for testing and in many other contexts. Each different variety requires its own specific heating element configuration.

Dryer heating elements rely on radiation and the transfer of heat through the air. Almost every dryer heating element involves an electric current passed through a metal wire of some kind. That wire is often a nickel-chrome alloy-twisted wire. After an electric current is applied, heat is generated because of electrical resistance. Many electric heating elements are coated with ceramic insulation in order to increase electric resistance and heat generation capacity; some dryers are equipped with such heating elements, particularly kilns and other industrial dryers.

Dryer heating elements are available in many different sizes and shapes to accommodate the many different dryer configurations in which they are employed. Variables like dryer size, construction, composition, required heat generation capacity and materials to be heated factor into what constitutes an appropriate heat generation material.

Dryer heating elements usually have a shorter lifespan than other dryer components like hoses and insulation. For this reason, dryer heating elements often must be replaced or repaired sooner than other dryer components. Replacement dryer heating elements can be standard or custom made to fit the application.

Carefully pairing the right dryer heating element with the rest of the dryer components contributes to longer, safer and more effective dryer operation.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services