Ceramic materials like silicon carbide are used to create ceramic heating components, which generate heat. They are employed in various applications as well as low- and high-temperature furnaces and ovens. Read More…

Hotwatt manufactures a complete line of heating elements for a wide range of uses. We offer a broad product line from electric to cartridge and countless other systems as well. For those difficult applications, custom products are also available.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

Small-diameter, screened electrical resistance wires describe our heating elements. Braze them onto another metal piece; they'll fit a tight-bending radius, and the generation of heat at their placement reduces power consumption and loss. Call us or check our website for more information.

More Ceramic Heating Element Manufacturers

What are Ceramic Heating Elements?

A ceramic heater's heating elements are in direct or close proximity to the material or space being heated. Products that melt, cook, dry, warm, seal, or reform material can use ceramic heating components.

Ceramic heating components are also found in a variety of industrial and consumer goods, including hair dryers, space heaters, toasters, and irons. Ceramic heating components may provide a lot of heat that is dispersed evenly.

Due to their greater capacity for generating heat and their ability to distribute it evenly, they are regarded by many professionals as being superior to wire heating elements. They are also less likely to start fires and have a longer lifespan than wire heating elements. In addition, because of their high electrical resistance, ceramic heating components are extremely efficient heaters.

The capacity of a heating element to generate heat depends on how electrically resistive it is. The durability and longevity of ceramic heating elements are also superior to those of other heat element types.

How Ceramic Heating Elements Work

Electric resistance heating, the heat produced by a material with high electrical resistance while a current is conducted through it, underlies the operation of metal and ceramic heating components.

Metal or ceramic heating components produce heat by resisting the flow of electricity when a current passes through them. Although furnace designers have a wide range of heating element options at their disposal, ceramic heaters typically fall into one of two categories: exposed ceramic rods or coils, ribbons, and wires of an alloy encased in a ceramic insulating plate.

These heating elements all function according to the same basic idea. Under ideal circumstances, the element should resist current flow and produce heat radiating into the heat treatment chamber. As 100% of the given electricity is potentially turned into heat, this has a considerably higher efficacy over combustion.

However, many interrelated events can impact these two fundamental features. These fundamentally significant properties include watt loading, voltage, element size, alloy composition, and device architecture, to name just a few. The disadvantage of exposed silicon carbide ceramic heating components is that they are prone to cross-reactivity with ambient gases at high temperatures because the material is not fully densified.

The conductive cross-section of the element may be impacted by these processes, which over time results in a progressive rise in electrical resistance. For example, a silicon carbide ceramic heating element's resistance may rise by as much as 300 percent before it reaches the end of its useful life.

Types of Ceramic Heaters

The different types of ceramic heaters include:

Tubular Heaters

Tubular heaters are made of a resistance wire packed with a ceramic insulator and housed inside a tubular metal sheath body. The ceramic insulator is characterized by high heat conductivity and dielectric strength. It stabilizes the resistance wire mechanically and guards against oxidation and corrosion. As a result, the tubular heater is made safer, more efficient, and less likely to catch fire.

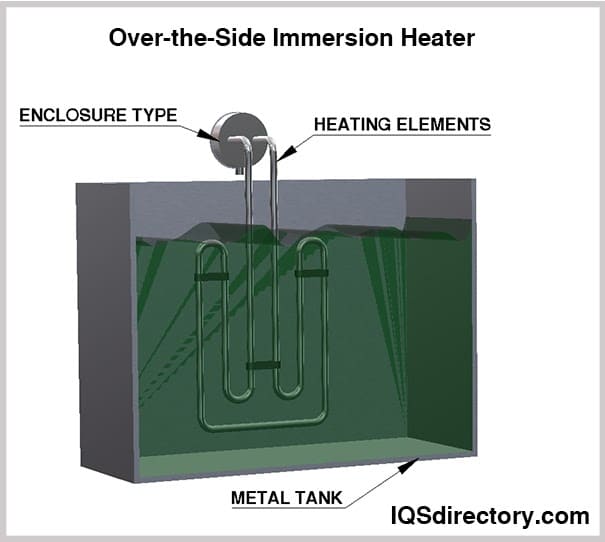

Immersion Heaters

Liquids and gasses can be heated directly in tanks and vessels using immersion heaters intended for this purpose. These heaters are made of several hairpin-shaped heating elements made of tubular material.

A resistance wire is also used in the tubular heating elements of flanged immersion heaters, which are housed in a bed of ceramic insulators and a sheath. Convective heating occurs when the fluids touch the metal sheath and raise their temperature.

Applications of Ceramic Heating Elements

- A heater intended to keep food items warm would be an illustration of one of these heaters. Instead of indirectly warming the substance through fans or ducts, the heating element warms it directly.

- Immersion heaters can occasionally use ceramic heating components. An immersion heater uses heating elements that can be submerged in a liquid to heat the material in the immediate vicinity.

- Ceramic heating elements are used in numerous industrial and manufacturing applications, such as heaters, ovens, dryers, and furnaces. Products that melt, cook, dry, warm, seal, and reform material can use ceramic heating components.

- Ceramic heating components are also found in a variety of industrial and consumer goods, including hair dryers, space heaters, toasters, and irons.

Choosing the Proper Ceramic Heating Element Supplier

To ensure you have the most beneficial outcome when purchasing ceramic heating elements from a ceramic heating element supplier, it is important to compare several companies using our directory of ceramic heating element suppliers. Each ceramic heating element supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each ceramic heating element company website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple ceramic heating element companies with the same form.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services