Heating coils are useful equipment to produce heat. They are incorporated into commercial, consumer, and industrial appliances and equipment for various uses. Converting electricity to heat is how heating coils work. The most popular type of heating element is one with heating coils. In addition to numerous other uses, they produce heat in machinery and buildings. Usually constructed of metal or ceramic, an electrical current heats the coil. Space warmers, electric ovens, and hair dryers are common examples of this design. Read More…

Hotwatt manufactures a complete line of heating elements for a wide range of uses. We offer a broad product line from electric to cartridge and countless other systems as well. For those difficult applications, custom products are also available.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

Small-diameter, screened electrical resistance wires describe our heating elements. Braze them onto another metal piece; they'll fit a tight-bending radius, and the generation of heat at their placement reduces power consumption and loss. Call us or check our website for more information.

More Heating Coil Manufacturers

Types of Heating Coils

Electric heating coil elements are foundational components in modern heating technology, used extensively in residential, commercial, and industrial applications. They are available in two broad categories: open heating coils and covered (or enclosed) heating coils. Each type offers unique benefits and is engineered for specific use cases and environments, making it essential to understand their differences when selecting heating solutions for your needs.

Open Electric Heating Coils

Open coil heating elements feature exposed resistance wire, typically made from high-performance alloys such as nickel-chromium (nichrome), kanthal, or copper. The lack of a protective sheath allows open coils to heat up and cool down extremely quickly, resulting in rapid thermal response. This makes them ideal for applications requiring fast, direct heat transfer and efficient energy usage.

However, the exposed nature of open coils means they are more susceptible to physical damage, oxidation, and contamination. Maintenance is generally straightforward, with easy access for inspection and replacement, but these coils are best used in controlled environments or where safety guards can be implemented.

Common applications for open coil heating elements include:

- Space heating (such as electric space heaters and fan-forced heaters)

- Duct heating systems in HVAC installations

- Pipe trace heating to prevent freezing or maintain process temperatures

- Heating metal tubing in industrial processes

- Tank heating for fluids and chemicals

- Forced air heating units

- Industrial and commercial ovens

Covered (Enclosed) Heating Coils

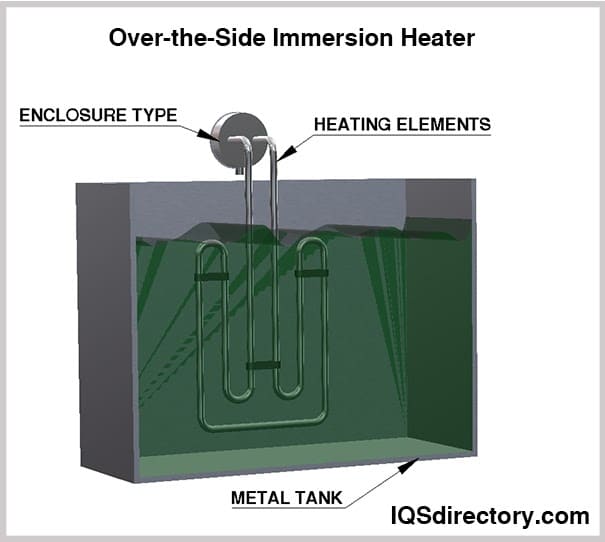

Covered or enclosed coil heaters are manufactured by encasing the resistance wire within a metal or ceramic sheath. This protective barrier shields the heating element from direct exposure to corrosive environments, dust, moisture, and accidental contact. As a result, covered coils are often used in applications where safety, durability, and contamination resistance are paramount.

Typical sheath materials include stainless steel, Incoloy, copper, and aluminum, each offering different advantages for specific environments—such as chemical resistance, mechanical strength, or thermal conductivity. The added protection may slightly reduce the speed of heat transfer compared to open coils, but it dramatically extends service life and enhances safety.

Covered heating coils are widely used in:

- Immersion heaters for water, oil, or chemical tanks

- Process heating in food and beverage production

- Medical sterilization equipment

- Electric boilers

- Commercial dishwashers and laundry equipment

- Hazardous or corrosive environments

Applications of Heating Coils

Heating coils are ubiquitous in both consumer and industrial equipment, providing reliable and efficient heat generation for a vast array of uses. They are designed in various shapes, sizes, and wattages to suit precise application requirements, ensuring optimal thermal performance and energy efficiency.

In household appliances, heating coils are essential components in space heaters, electric ovens, cooktops, toasters, dishwashers, clothes dryers, and hair dryers. Their broad adoption is due to their cost-effectiveness, rapid response, and ease of integration into compact devices.

For commercial and industrial applications, heating coils are engineered to deliver consistent heat in demanding environments. For example, ceramic-coated heat coils in commercial ovens provide enhanced heat distribution and protect against grease, chemical spills, and high operating temperatures.

Industrial processes rely on specialized heating coil designs for material processing, drying, curing, melting, and temperature regulation. Some furnace setups combine air blowers with heating coils to preheat air, while others use coil heaters for direct immersion or radiant heating.

Notable machines and equipment using heating coils include:

- Metal analysis and metallurgical instruments

- Plastic injection molding machines

- Hot water storage (Speicher) tanks

- Pulp and paper processing equipment

- Oil reclamation and purification systems

- Blow molding machinery

- Industrial extruders

- Automated packaging equipment

- Bag-sealing machines and continuous heat sealers

- Hot stamping presses for labeling and printing

- Labelling and coding equipment

Specialized Use Cases for Heating Coils

Are you searching for the ideal heating solution for a unique industrial need? Heating coils are frequently customized for:

- Controlled atmosphere furnaces for heat treatment

- Cleanroom and semiconductor manufacturing

- Pharmaceutical and chemical processing

- Environmental test chambers

- Glass and ceramics production

- Freeze protection and temperature maintenance for pipelines

- Food warming and holding equipment

Explore our immersion heater elements and related products to discover solutions tailored for liquid heating, chemical processing, and other demanding applications.

Design of Heating Coils

Heating coils are engineered with a focus on material selection, geometry, and electrical characteristics, ensuring optimal performance and safety in every application. Selecting the right alloy—such as nichrome, kanthal, or copper—directly impacts the coil's electrical resistance, thermal output, and longevity.

Coil geometries vary widely to suit installation constraints and heat distribution requirements. Pre-formed shapes, custom-bent coils, and modular designs give engineers and end-users flexibility to meet even the most challenging heating scenarios.

- Spirally coiled heating elements – Compact, ideal for confined spaces, and commonly used in cartridge heaters and tubular heating elements.

- Star-wrapped coils – Create turbulence within ducts and pipes, improving heat transfer efficiency in flowing air or liquid systems.

- Flat and ribbon coils – Used in applications needing maximum surface contact or where uniform radiant heat is required.

- Custom-formed coils – Engineered for specialized equipment, from laboratory instruments to industrial machinery.

When evaluating coil designs, consider key specification factors such as watt density, voltage rating, maximum operating temperature, resistance to corrosion, and physical dimensions. For harsh environments or corrosive media, select coils with advanced sheath materials or protective coatings.

Coil heaters can reach temperatures up to 1200°F (650°C) and deliver uniform heat profiles across large or targeted areas. Insulation materials—such as ceramic, fiberglass, or mica—are used to improve thermal efficiency and electrical safety. Metals like stainless steel, brass, aluminum, and Incoloy are chosen based on compatibility with the heated media and required service life.

Some coil heaters are engineered for submersion in liquids, while others are designed for air or surface heating. It's critical to match the heating coil’s design, material, and power rating to the specific demands of your application for maximum efficiency, safety, and longevity.

Frequently Asked Questions About Heating Coil Design

- How do I select the right heating coil material for my application? – Consider the medium (air, water, oil, chemicals), desired temperature, corrosion resistance, and electrical requirements.

- What is watt density, and why does it matter? – Watt density (W/in² or W/cm²) determines how much heat is generated per unit area. A higher watt density is suitable for fast heating but may reduce coil life in some conditions.

- Can heating coils be custom-shaped for specialized equipment? – Yes, many manufacturers offer custom heating coil fabrication to match complex geometries and unique installation requirements.

Advantages of Heating Coils

Flexible Shapes and Customization: Electric coil heaters are highly ductile, enabling them to be shaped into virtually any configuration—straight, spiral, star, or custom-formed—making them suitable for retrofits and new installations alike.

Rapid Temperature Response: The low thermal mass of heating coils allows for quick heat-up and cool-down cycles, making them ideal for precision temperature control in industrial, commercial, and residential applications.

Durability and Reliability: With proper material selection and engineering, heating coils can endure repeated thermal cycling, harsh environments, and long operating hours with minimal maintenance.

Versatility and Wide Range of Applications: From sub-freezing cold storage to high-temperature process equipment, electric coil heaters are deployed in countless scenarios, including gas heating, liquid immersion, air heating, and surface heating.

Climatic Resilience: Advanced engineering allows heating coils to withstand severe weather, corrosive atmospheres, and demanding industrial conditions. In the oil and gas sector, they are critical for pipe trace heating and flow assurance.

Space Efficiency and Safety: Electric heating coils contain fewer moving parts, resulting in compact designs that minimize installation footprint. Integrated control boxes and safety devices—such as thermal cutoffs and ground fault protection—enhance operational safety, especially in immersion heater systems.

Energy Efficiency: Electric heating coil elements deliver high conversion efficiency, directly converting electrical energy to heat with minimal losses. This translates to cost savings, reduced emissions, and easier integration with automated process controls.

How to Select the Best Heating Coil for Your Application

Choosing the right heating coil is a crucial step in ensuring process reliability, energy efficiency, and safety. Here are some important decision-making factors to consider:

- Application Type: Is the coil for air heating, liquid immersion, surface heating, or another use? Each requires specific design features.

- Required Temperature and Wattage: Define the maximum temperature and total heat output needed for your process.

- Operating Environment: Assess exposure to corrosive chemicals, moisture, dust, or physical impact.

- Installation Constraints: Measure available space, mounting options, and power supply compatibility.

- Material Compatibility: Select alloys and sheath materials based on thermal conductivity, corrosion resistance, and mechanical strength.

- Regulatory Compliance: Ensure the heating coil meets industry standards and safety certifications for your sector.

- Budget and Total Cost of Ownership: Factor in initial cost, expected lifespan, maintenance needs, and energy consumption.

Not sure which heating coil technology is right for your needs? Ask these questions as you search for a solution:

- What is the primary function of the heating coil in my process?

- Is rapid temperature change important, or is steady-state heating preferred?

- Will the coil be exposed to corrosive or hazardous substances?

- What are the preferred maintenance intervals and replacement part availability?

Choosing the Right Heating Coil Manufacturer

To achieve optimal results and long-term satisfaction with your heating solution, it’s vital to partner with a reputable heating coil manufacturer that understands your industry, process requirements, and budget. Our comprehensive directory of heating coil manufacturers lets you compare multiple companies based on their expertise, capabilities, and product offerings.

Each manufacturer’s profile page highlights their specialties—such as custom coil fabrication, high-temperature materials, energy-efficient designs, or rapid prototyping—enabling you to find the best match for your unique project.

Ready to get started? Use our website previewer to quickly review each heating coil supplier’s online presence and offerings. When you’re ready to engage, our RFQ (Request for Quote) form lets you reach out to multiple manufacturers simultaneously, streamlining the procurement process.

For additional guidance, explore our resources and guides on electric heating elements, immersion heater elements, and related technologies to expand your knowledge and make an informed decision.

Take the Next Step: Find the Ideal Heating Coil Solution

Whether you’re upgrading an existing system or designing a new process, selecting the right heating coil can make a significant impact on performance, efficiency, and operational cost. Explore our curated directory, compare manufacturers, and leverage our expertise to source custom heating coils, replacement heating elements, and high-performance coil heaters for your industry.

Still have questions? Contact us or browse our FAQs to learn more about heating coil design, maintenance, installation, and safety best practices. Our experts are here to help you find the perfect heating solution for your specific needs—whether it’s for industrial, commercial, or residential applications.

Ready to improve your heating process? Start your search for the best heating coil manufacturers here and take the first step toward energy-efficient, reliable, and cost-effective heating solutions.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services