Infrared heaters frequently use quartz heating components, which offer a source of quick heating. Electrical currents are transformed into infrared rays by passing them through specially crafted resistors in quartz infrared heating elements. Read More…

Hotwatt manufactures a complete line of heating elements for a wide range of uses. We offer a broad product line from electric to cartridge and countless other systems as well. For those difficult applications, custom products are also available.

At Cartridge Heaters Maxiwatt, we specialize in producing high-quality heating elements designed to meet the diverse needs of our clients across various industries. Our advanced heating elements are engineered with precision and built to last, providing reliable and efficient performance in even the most demanding applications. Utilizing cutting-edge manufacturing techniques and the finest...

Small-diameter, screened electrical resistance wires describe our heating elements. Braze them onto another metal piece; they'll fit a tight-bending radius, and the generation of heat at their placement reduces power consumption and loss. Call us or check our website for more information.

More Quartz Heating Element Manufacturers

What are Quartz Heating Elements?

Quartz heating elements are advanced heating components that utilize the properties of quartz to emit radiant heat, primarily through infrared radiation. This technology is widely used in a variety of industrial heating and commercial heating applications due to its efficiency, reliability, and versatility. Infrared radiant heating works by directly warming surfaces and objects, rather than heating the air, making quartz heaters highly effective in spaces where targeted heat delivery is needed.

Infrared heat constitutes a segment of the electromagnetic spectrum, falling just below visible light in frequency. All objects emit and absorb this form of energy, and hotter objects radiate more heat energy. Quartz heaters capitalize on this principle—most quartz heating elements are designed to maximize the emission and direction of infrared energy for optimal performance in various settings, including manufacturing, laboratories, and residential environments.

The wavelength of infrared rays generated by quartz elements can be tailored to suit specific applications and operational distances. Quartz itself is favored as a heating element material because of its exceptional heat resistance, low absorption, and outstanding electrical insulation properties. These attributes make it an ideal choice for high-performance heating systems.

How Do Quartz Heaters Work?

Quartz heaters operate by converting electrical energy into infrared radiation, which is then directed onto objects or people within the target area. Optical reflectors are often integrated into these systems to focus and distribute energy in precise heat patterns, maximizing efficiency and heat coverage. The operation of a quartz heater is analogous to the way sunlight warms objects, as both involve parallel rays traveling through space and directly heating anything in their path.

This direct method of heat transfer makes quartz heaters ideal for both indoor heating and outdoor heating applications. Unlike conventional convection-based heaters, quartz heating is not affected by wind or air currents, since the infrared energy bypasses the air and is absorbed directly by surfaces, people, and equipment. This feature makes quartz heaters particularly suitable for large-space heating and spot heating in areas such as warehouses, factories, garages, patios, and workshops.

A typical infrared quartz heater consists of a tightly wound heating coil housed within a robust quartz tube. When electricity passes through the coil, it heats up rapidly, and the heat energy is absorbed and stored by the quartz tube. The tube serves a dual purpose: it shields the heating element from physical damage and prevents unwanted convective heat loss, ensuring that most of the energy is delivered as radiant heat.

Once the quartz tube reaches the optimal temperature, radiant heat is emitted outward, providing efficient zone heating that is immediately felt by occupants and objects in the area. The specific wavelength of the emitted infrared rays can be engineered to match the heating requirements of the application—whether that is gentle warmth for comfort heating or intense energy for industrial processing.

Research shows that the infrared heat produced by quartz elements is nearly perfectly tuned for human comfort. Because the infrared spectrum used by these heaters is minimally absorbed by air, almost all the heat is delivered to objects and people in the path of the rays, resulting in minimal energy wastage and fast, effective heating.

Types of Quartz Heater Elements

When selecting a quartz heating element for your needs, it's important to understand the different types available and their respective advantages. The main categories include:

- Medium-wavelength tube heaters: These heaters feature a quartz tube with an internal heating element. They are commonly arranged in banks to form extensive heating arrays, making them ideal for industrial drying and curing processes. Their balanced wavelength output is suitable for many manufacturing applications, including paint drying, plastics forming, and textile processing.

Short Wavelength Tube Heaters

Short wavelength tube heaters share a similar construction to their medium-wavelength counterparts, but use tungsten elements housed within a quartz tube that is sealed with a noble gas. These heaters emit high-intensity infrared radiation with shorter wavelengths, making them exceptionally effective for metal heating, powder coating, and other applications requiring rapid, deep penetration of heat. Their fast response time and high output make them a top choice for high-speed production lines and surface treatment tasks.

Quartz Panel Heaters

Quartz panel heaters are distinguished by their solid face, which is made from fused quartz. The heating element is embedded just below the surface, enabling uniform heat distribution across a larger area. These higher-mass heaters are preferred for applications that demand consistent energy output over broad surfaces, such as space heating in offices, commercial buildings, and laboratories. They are also increasingly popular for residential heating due to their sleek design and quiet, efficient operation.

Surface Tube Heaters

Surface tube heaters are constructed by wrapping a heating element around the outside of a quartz tube. This configuration allows for both convection heating and infrared heating, providing versatile performance in a variety of environments. Surface tube heaters are well-suited for industrial furnaces and ovens where precise temperature control is necessary for both the surrounding air and the target objects. They are commonly used in thermal processing and annealing operations.

Quartz Lamp Heaters

Quartz lamp heaters, sometimes referred to as quartz infrared lamps, incorporate an aluminum casing with a polished reflector to direct the infrared rays. These elements typically operate at wavelengths below five micrometers, with tungsten filaments capable of running at temperatures around 2500° K. This results in a high watt density and intense short-wavelength radiation, making quartz lamp heaters invaluable for high-speed production applications, plastic welding, adhesive curing, and surface finishing. Their rapid response time and efficient heat transfer make them a staple in modern manufacturing environments.

Quartz Tube Elements

Quartz tube elements are designed using a resistance coil that runs through several parallel quartz tubes and is encased in a highly reflective body, often made of aluminized steel. These elements are engineered for radiant heating applications and are especially effective for processing heat-sensitive materials such as certain plastics, films, and medical products. Their design ensures that heat is delivered precisely to the target area, minimizing energy loss and enhancing process control.

Key Benefits of Quartz Heating Elements

Quartz heating elements offer a host of advantages that make them an attractive choice across a wide spectrum of industries and environments. Here are some of the most important benefits:

- Energy Efficiency: Quartz heaters provide direct, targeted heat. Little energy is wasted heating the air, resulting in lower operational costs and enhanced energy savings.

- Fast Response Time: With rapid heat-up and cool-down cycles, quartz elements allow for precise temperature control and quick adaptation to changing process requirements.

- Low Maintenance: The robust design and minimal moving parts make quartz heaters highly durable and easy to maintain, reducing downtime and maintenance expenses.

- Versatility: Quartz heating elements are available in a variety of configurations, wattages, and sizes, making them suitable for everything from industrial process heating to commercial space heating and residential comfort heating.

- Clean and Silent Operation: Quartz heaters generate no combustion by-products and operate silently, making them ideal for cleanroom environments, laboratories, and residential settings.

- Consistent Performance: The infrared output of quartz elements is stable and consistent, ensuring reliable results in demanding applications such as food processing, pharmaceutical manufacturing, and electronic assembly.

Applications and Use Cases for Quartz Heating Elements

Quartz heating elements are chosen for their unique combination of efficiency, control, and versatility. Here are some of the most common and high-value use cases:

- Industrial Heating: Used extensively for drying, curing, preheating, and annealing processes in manufacturing plants, automotive assembly lines, and electronics production.

- Commercial and Institutional Heating: Provide energy-efficient warmth in warehouses, sports arenas, churches, hospitals, and commercial kitchens.

- Residential Heating: Popular for use in bathrooms, living rooms, basements, and sunrooms where fast, comfortable heat is desired without the noise or drafts associated with traditional systems.

- Laboratory and Cleanroom Applications: Quartz heaters offer contamination-free, precisely controlled heat for sensitive environments in scientific research, pharmaceutical manufacturing, and semiconductor fabrication.

- Outdoor and Patio Heating: Infrared quartz heaters are a preferred solution for extending outdoor comfort in restaurants, patios, and recreational venues, as they are unaffected by wind and deliver instant warmth to people and objects.

- Specialty Applications: Employed in medical device manufacturing, food service equipment, greenhouse cultivation, and plastic forming where controlled, localized heating is crucial.

Buyer’s Guide: How to Select the Right Quartz Heating Element

Selecting the best quartz heating element for your specific needs involves evaluating several key factors to ensure optimal performance, longevity, and cost-effectiveness. Consider the following when researching and purchasing quartz heating solutions:

- Application Requirements: What is the primary use case? Is the heater needed for process heating, space heating, or a specialized application such as medical device sterilization or food preparation?

- Wavelength and Output: Different applications require different infrared wavelengths. For example, short-wavelength heaters are ideal for deep penetration, while medium-wavelength models are better for surface heating. Consult with manufacturers to select the ideal type for your needs.

- Power and Size: Determine the wattage and physical dimensions needed to achieve the desired heat output and coverage area. Custom sizing may be available for unique installations.

- Control Options: Some quartz heaters offer integrated controls for temperature regulation, timers, and programmable settings to enhance efficiency and convenience.

- Safety Features: Look for heaters with built-in safety mechanisms such as thermal cutoffs, tip-over protection, and insulated casings, especially for residential and public spaces.

- Supplier Reputation: Always choose a reputable quartz heating element manufacturer or supplier with a track record of quality products, responsive support, and reliable delivery.

Frequently Asked Questions About Quartz Heating Elements

What is the lifespan of a quartz heating element?

Most quartz heating elements are rated for thousands of hours of operation. Longevity depends on the quality of the element, operating temperatures, and the environment in which it is used. It's common to achieve 5,000–10,000 hours with proper usage and maintenance.

Are quartz heaters energy efficient?

Yes, quartz heaters are known for their energy-efficient performance. By delivering heat directly to people and objects, they minimize energy loss and reduce overall heating costs.

Can quartz heating elements be used for outdoor applications?

Absolutely. Quartz heaters are highly effective outdoors due to their resistance to wind and ability to deliver instant, localized heat. This makes them a top choice for patios, terraces, and outdoor seating areas.

How do I maintain and clean my quartz heater?

Maintenance is minimal. Periodically inspect the heater for dust buildup and wipe the quartz tubes with a soft, dry cloth. Avoid using water or abrasive materials. Always disconnect power before cleaning.

Where can I find replacement quartz heating elements?

Most manufacturers and suppliers offer replacement quartz heating elements. It's important to select elements that match your heater's specifications for wattage, size, and connection type. Find heater element manufacturers here.

Explore: Choosing the Correct Quartz Heating Element Supplier

To achieve the best results when purchasing quartz heating elements from a supplier, it’s essential to research and compare multiple companies. Our comprehensive directory of quartz heating element suppliers allows you to evaluate supplier capabilities, technical expertise, and manufacturing strengths. Each supplier profile includes detailed information about their experience, certifications, and application specialties.

Use our patented website previewer to quickly assess each quartz heating element company’s specialties and product lines. For a streamlined procurement process, our easy-to-use RFQ (Request for Quote) form enables you to contact several suppliers simultaneously, ensuring you receive competitive quotes and tailored recommendations.

Ready to take the next step? Browse our directory of trusted quartz heating element manufacturers, compare product offerings, and request quotes to find the perfect heating solution for your application.

Still Have Questions About Quartz Heating Elements?

Looking for custom quartz heating solutions? Need help specifying the right heater for your process or facility? Contact our team of heating technology experts.

Compare, connect, and succeed—discover the optimal quartz heating technology for your industrial, commercial, or residential needs today.

Cartridge Heaters

Cartridge Heaters Electric Heaters

Electric Heaters Heating Elements

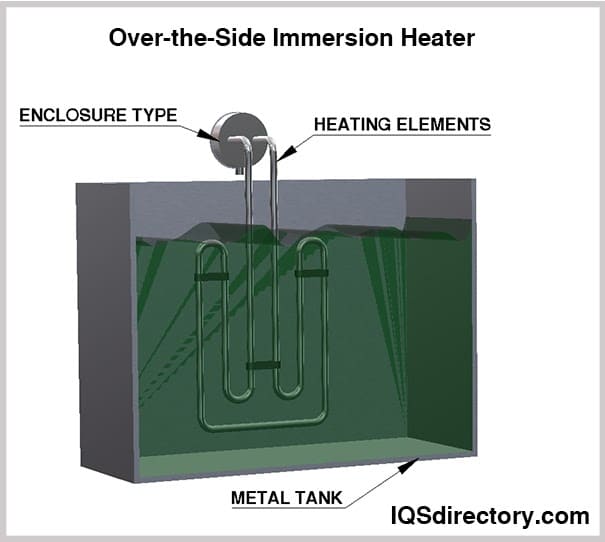

Heating Elements Immersion Heaters

Immersion Heaters Infrared Heaters

Infrared Heaters Air Conditioners

Air Conditioners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services